Introduction: Consistency Beats Speed on the Line

Consistency is the real profit lever in modern automation. Picture a late shift on a Nairobi assembly cell: the robot nails cycle time, yet tiny variances creep in and quality slips. Those variances almost always trace back to robotics parts working under stress, not headlines about “AI.” When the wrong gearboxes, encoders, or power converters stack up, a 0.3% drift can erase your margin (pole pole, but the loss accumulates). In many plants, three minutes of unplanned pause per hour adds up to a 4–6% throughput dent. The fix is not just more force; it is smarter choice and tighter integration of industrial robot components. So here is the question that matters for your line: how do you engineer repeatable output when every link—actuator, drive, network—has its own failure mode? Let us map the hidden levers, then compare what actually moves the needle. Next, we go deeper into the component stack and why traditional picks often underperform.

Part 2: Hidden Pain Points Inside the Component Stack

Where do teams actually struggle?

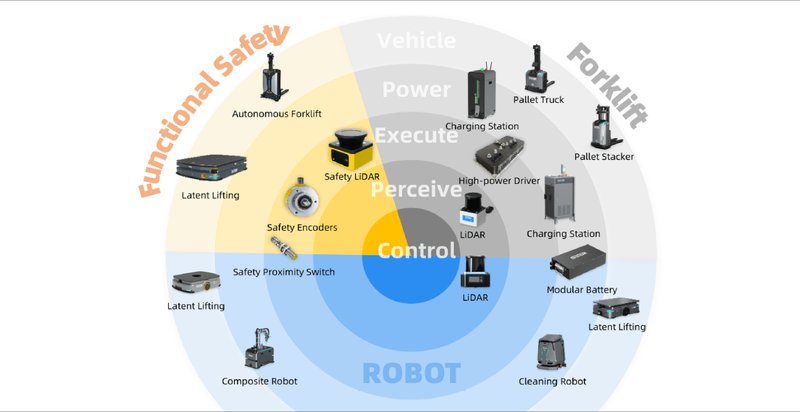

In Part 1, we spoke about stability at the cell level. Now, let’s get direct about the component layer—the level where small gaps turn into daily rework. Many teams assume a bigger motor cures missed picks—funny how that works, right?—but poor encoder resolution, backlash in a harmonic drive, or servo drives tuned to the wrong load profile cause the real wobble. Add noisy cabling that disrupts EtherCAT timing, and you get jitter that a PLC patch cannot mask. Even “strong” grippers slip when force-torque sensors drift with heat. And when edge computing nodes run vision plus control on the same core, latency spikes hit the PID loop. The machine looks fine; the parts tell a different story.

Look, it’s simpler than you think, yet easy to miss. Undersized power converters cause brownouts during fast accelerations, then operators blame the robot. Cheap encoders read fine at low speed, then alias under vibration and the end-effector misses by 0.4 mm—small, until it is not. Cables without proper shielding invite EMI, so time sync slides and quality follows. And thermal creep? It shifts clearances across a shift, especially near ovens or weld bays. The lesson is tough but fair: spec by the worst hour, not the best minute—and design industrial robot components as a system, not a shopping list. Otherwise, you will keep tuning software to hide hardware choices.

Part 3: Forward-Looking Principles for Component Choice

What’s Next

Here is the comparative lens we need going forward. New servo architectures blend model-based control with adaptive feedforward, so the controller predicts load changes instead of fighting them late. Wide-bandgap GaN power converters cut switching losses, holding voltage under sharp torque steps. Time-Sensitive Networking (TSN) offers deterministic timing similar to EtherCAT yet scales across mixed vendors—handy when vision, safety, and motion must stay in lockstep. Meanwhile, smarter encoders fuse IMU data to survive vibration without drift. Put simply, precision now comes from coordination, not brute specs—and yes, it matters.

On the integration side, software-defined I/O and ROS 2 executors let you partition real-time threads, keeping motion control isolated from machine vision spikes. Pair that with built-in condition monitoring on motors and gearboxes, and you predict backlash growth before it bites. Digital twins for industrial robot components now mirror thermal and load behavior, so you “tune once, validate everywhere.” The summary takeaway: the weak link moves over time. Today it might be encoder noise; tomorrow, network jitter. So evaluate components as a living set—measured, logged, and easy to retune. To choose wisely, use three metrics: 1) end-to-end jitter budget under peak load (ms, 95th percentile), 2) thermal drift of sensors and actuators across a shift (zero-to-zero error), and 3) maintainability under fault—mean time to diagnose and restore (MTTR). Measure these in trials, not brochures; the numbers will tell you what to buy. For a grounded view of the ecosystem and how vendors interoperate across the stack, see SEER Robotics.